Ultimate Guide to Water Heaters

No one likes to think of their water heater until it malfunctions

The water heater is an oft overlooked home appliance that every can appreciate, and it can cause major discomfort when it isn’t operating properly.

Knowing first about water heaters is important, then we’ll delve into some tips and tricks for keeping your water heater operating at optimal performance.

Types of Water Heaters

There are basically three types of water heaters: standard tank, tankless and heat pump water heaters.

- Conventional Water Heaters

Conventional water heaters, also called storage tank water heaters, are the most common type–they consist of an insulated tank in which water is heated and stored until needed. Natural gas water heaters typically use less energy and cost less to operate than electric water heaters, but can be more expensive and difficult to install.

Conventional water heaters require regular maintenance to operate efficiently and effectively over the years. They must be drained and flushed, removing sediment and buildup, at least once a year. The statistical life expectancy of a storage tank water heater is 10-12 years, depending on care and maintenance.

- Tankless Water Heaters (On-Demand)

Tankless water heaters use intense flashes of heat against water-filled coils to heat water on demand. Tankless water heater plumbing systems are more energy efficient than conventional storage tank models, but tend to have higher up-front costs.

Tankless water heaters can be sized to provide a continuous flow of hot water, making them suitable for large families that use a lot of hot water at one time. They’re also better suited for use with natural gas, though they may require installation of a larger diameter gas line, a potentially costly endeavor. Electric tankless models may require an upgrade of the home’s electrical capacity.

Like storage tank water heaters, tankless water heaters need to be descaled of minerals at least once a year to keep them functioning reliably.

- Heat Pump Water Heaters

Heat pump water heaters, also called hybrid electric water heaters, capture heat from the air or ground and transfer it to the water. They cost more up front than standard electric models, but use about 60% less energy, meaning homeowners tend to see a return on their investment in the form of lower energy bills.

Hybrid electric heat pump water heaters don’t work well in very cold spaces. Because the heat pump is on top of the appliance, a hybrid unit may need as much as a 7-foot clearance from floor to ceiling.

Water Heater Efficiency Factor

The Efficiency Factor, or EF, is the measure of how efficiently your water heater converts energy to transfer heat into you water. With two identically-sized water heaters using the same amount of water, the unit with a higher EF, will use less energy.

Standard tank water heaters usually have an EF of .58-.62 (meaning 58-60% efficient), while Energy Star models are rated at .67 or higher. Electric tank water heaters have very high EFs, above .90, but the energy source is much less efficient, actually making them more expensive to run. Tankless water heaters offer high EFs (.92+) so they can offer energy savings throughout their lifetime.

Water Heater First Hour Rating

Usually the most prominent number found on your water heater tank will be the first hour rating. This is not the capacity of the tank, but rather how many gallons of hot water it can produce in its first hour of operation.

Factors such as the temperature of the water coming in to your home and your water pressure can impact this rating.

Water Heater Maintenance

Spring has almost arrived in many parts of the country. With the arrival of spring, it’s a good practice to do the recommended yearly water heater maintenance procedure.

Within the plumbing industry, there are often questions asked, references made to, and replies posted regarding either FLUSHING of a water heater tank or the DRAINING a water heater tank.

There are differences between draining and flushing and often the terms are accidentally interchanged and or used incorrectly. Draining refers to emptying the tank while flushing refers to removing debris from within the tank.

Safety Warnings pertaining to tank water heater draining/flushing:

- Follow all manufacturers instructions.

- Draining Requires Turning Off The Appliance First.

- Be aware that HOT water can cause personal injuries and damage to surrounding areas.

Water Heater Tank Draining Procedure:

At times it may become necessary to drain {empty} the water heater tank for various reasons. Replacing the tank with a new tank, moving the tanks current location to another location, installing replacement parts to the current tank, etc.

If you have a need to do so, the very first step is to turn OFF the gas or electric supply to the tank! Without water in the tank, the temperature sensing element or elements will cool off, due to the lack of hot water.

Without water in the tank, it is essential to turn off the energy source prior to draining the tank. Failure to do so will cause permanent damage to the control, burner, electrical elements, tank and any other parts.

Second step in the draining process’s to turn OFF the incoming water supply. The COLD water inlet supply valve will be on the inlet water pipe located on the right side of the tank at the top.

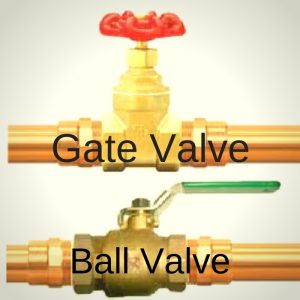

The valve may be one of two commonly used varieties:

The valve may be one of two commonly used varieties:

- A gate valve, which has a round knob that is turned in wards {clockwise} until fully seated in the closed position.

- The other type is a ball valve variety. This valve will have a lever that is turned so the lever handle is no longer parallel to the pipe. Instead, the lever handle will be across the pipe.

Third step is to OPEN at least one HOT water faucet within the house. By doing so, internal water pressure within the tank will be relieved.

Air will than be allowed to enter through the opened faucet to help displace the water in the tank. Failure to execute this step will result in the tank not completely emptying.

Fourth step is to locate the faucet {Spigot} on the tank. These faucets are always located near the bottom of the tank next to the thermostat temperature control dial or lower thermostat on electric water heater tanks.

Fourth step is to locate the faucet {Spigot} on the tank. These faucets are always located near the bottom of the tank next to the thermostat temperature control dial or lower thermostat on electric water heater tanks.

On to this spigot, attach a common garden hose and place the other end of the hose where the exiting hot water will be safe to flow and the hot water will not cause damages to the surrounding areas.

Once the garden hose is attached to the spigot or faucet on the tank, OPEN the valve and allow the entire tank to DRAIN until fully emptied. This process may take several minutes. Be patient.

Water Heater Tank Flushing Procedure:

It is often recommended and also a good idea to FLUSH a water heater tank annually.

The reasoning behind this maintenance procedure is to flush out accumulated sediment and rust particles that will naturally settle and on the bottom of the tank.

Sediment is found within all supplies of water more or less to some degree. Rust comes from the tanks interior, do to normal tank aging, the iron pipes within the houses piping system, those of the main supply, the streets piping system and other sources, depending on the water supply.

Tank Flushing Method:

To successfully accomplish the tank flushing task, simply attach a common garden hose to the water heaters faucet. To flush the tank, there is NO need to turn off the gas or electrical supply nor open any hot water faucet within the house.

Leave the inlet water supply valve ON. Just attach the garden hose to the tanks faucet, place the other end in a location where HOT water will do no damage and then simply OPEN the tanks faucet valve.

Leave the inlet water supply valve ON. Just attach the garden hose to the tanks faucet, place the other end in a location where HOT water will do no damage and then simply OPEN the tanks faucet valve.

Allow the existing HOT water to flow out until it does so cleanly and clearly. Depending upon the amount of rust and debris inside the tank, this step may take less than one minute or several minutes to completely and fully accomplish.

Be patient. Depending upon the amount of sediment and rust contained within the tank and how often this process is done, will determine the amount of time required to fully complete the tank flushing process.

Once this process is accomplished, CLOSE the tanks faucet valve.

Remove the garden hose from the faucet.

PRESTO! The FLUSHING is completed.

Check Out: How to Repair a Leaky Pipe

Water Heater Common Issues

-

Sizzling/Hissing Sounds:

That sizzling sound may be an early indication of a pin hole leak in the tank. To determine if that is so, turn the thermostat down to it’s lowest temperature setting for now.

Remove the decorative outer cover first. Than remove the inner firebox cover. Use caution. The metal may be hot but not likely if the outlet water is cold.

Look inside the firebox from a distance. You are looking for rust spots, rust scales or any such indications of such. If any are present, water is entering the firebox via a pin hole in the tank.

Depending upon the age of the tank, more than 10 years, likely there is an internal water leak in the tank. If the tank is less than 10 years old and you have the warranty to prove such, contact the mfg or a plumbing agent whom does warranty services for the brand.

If no warranty is available or the tank is out of warranty, etc, and rust, scale is evident, time for tank replacement. If no evidence is present, you can move back at arms length, turn up the T Stat to it’s highest setting and allow the burner to fire up.

Shortly there after water droplets should be visible dropping down onto the burner. If so, the tank will need to be replaced. If no water droplets are present after 10 minutes, tanks okay.

-

Combustion Air:

The formula for calculating the required amount of intake air is a minimum of 1 square inch of intake air per 1,000 BTU’s of appliance rating. Which means there must be 1 square inch of combustion air for each 1,000 BTU’s. Check the appliance rating plate.

Half of the total square inches must be in the ceiling or from 12 inches below the ceiling. The other half down at the base of the wall or 12 inches above the floor level. None of this air can come from within the living area of the home.

Each half of the half has to be equally spaced on either side. This rule applies to appliance in closets and inclosure’s. Attics, basements and sheds may have slightly different variations.

The supplied air must be supplied from outside or from either under the house on a raised foundation flooring or from the attic, if there is an attic. At no time should the air be taken from inside the living area. Codes vary. Check those in your area. Contact the local building and safety department in you city, town or local area.

Usually the gas utility company has service persons whom may provide insight and determinations. At other times it will take a plumbing professional, local inspector or building contractor.

-

Control Replacement:

To replace the entire control, turn off the incoming water valve. Open any hot water faucet to relieve the water pressure. Turn of the gas supply at the isolation valve where the flex connector is attached to the supply pipe.

Than remove the flex gas inlet line from the control valve. Remove the three lines under the control valve. No need to remove the parts from inside the firebox.

Using a mechanics strap wrench, wrap it around the outside diameter of the control and unscrew it out of the tank. Apply any type of common household oil, motor oil of any type or any type of automotive grease to the threads of the new part and screw it into the same place the old control was removed from.

Reinstall the three lines removed prior. Reconnect the gas flex line. Turn the water inlet valve back on. Open any hot water faucet to bleed out any air from the tank. Close sink faucet when done bleeding out air.

Turn on the gas supply shut off isolation valve on the supply pipe. Check for leaks with soapy water or leak detection soap. Light up the pilot. Turn on the burner. Recheck for leaks under the temperature control unit.

-

Temperature – Pressure Relief Valve Leaks:

If the water is coming out of the pressure-temperature valve, chances are that valve has rust and or sediment under the seat of the valves shut off.

Lifting the lever slightly will allow water to come out faster. Doing so may or may not flush out the sediment or rust. Lift the lever only part way not all the way. Just enough to allow water to forcefully flush out and just enough till the water appears clean.

Doing so might clean out the valves seat & washer. Not always but sometimes. If it seems to work, check it several times or the next few days. May or may not totally solve the problem.

If at anytime flushing the valve does not work, valve replacement is the only know solution. Tanking flushing is also recommended. The instructions for tank flushing can be found in a topic above.

The relief valve could be defective. Replacing it could solve the problem. Too much inlet water pressure and or the thermostats water temperature is set too high or there is sediment under the seat of the valve or in the tank.

-

Vent Testing:

A venting system not functioning correctly can be highly dangerous. Fumes can & will contain carbon monoxides. The amounts vary. None is acceptable in the living environment once the vent pipe heats up.

If there is suspicions of fumes entering the living area as a result of a blocked and or restricted venting system, it is highly suggested to have a professional test the system.

Most gas companies, natural or propane, do this simple test to ensure public safety. As well as plumbers & installers of water heaters and room/house heating agents, etc.

In order for drafting to take place, the venting system has to have hot gases attempting to escape up the vent pipe. The roof top vent cap does not allow much outside air to enter down the vent pipe.

If the roof top vent cap on the outside rooftop vent pipe is installed correctly, by this I mean not pushed down too much on the exposed pipe end, the cap will do it’s job.

Allow hot fumes and gases to escape out to the outside but not allow outside air forced by winds to back flow down the vent pipe.

The down draft deverter cap installed correctly on the top of the water heater will set up on it’s legs. The vent pipe onto it. The open space just beneath the cap and that above the water heaters built in flue pipe, is the space where inside air enters to the vent pipe to help dilute the hot escaping gases and fumes.

Once the water heater, a non power vented type, is warmed up after being on for 5 minutes max time, that space should be drawing in and up wards air very close to it.

The test to verify if inside air is being drawn up wards into the space between the water heaters flue and the down drafters cap, is to strike a stick match. Once a flame is established on the match, put the flame close to that open space.

The down draft diver tor cap installed correctly on the top of the water heater will set up on it’s legs. The vent pipe onto it. The open space just beneath the cap and that above the water heaters built in flue pipe, is the space where inside air enters to the vent pipe to help dilute the hot escaping gases and fumes.

Once the water heater, a non power vented type, is warmed up after being on for 5 minutes max time, that space should be drawing in and up wards air very close to it.

The test to verify if inside air is being drawn up wards into the space between the water heaters flue and the down drafters cap, the method is to use a stick match. Once a flame is established on the match, put the flame close to that open space.

Allow the flames to from the match to be drawn to wards the flow of air without being so close the air snuffs the match. The match flames should tilt in wards toward the cap.

This simple test shows the air flow direction. The flames can be allowed to burn down the match stick without going out until the flame gets close to your fingers.

If the reverse happens in the test, the flames snuff out, the match may be too close and or too far. If the match is held in the close to area but not inside the area space and the flames snuff out or point away from the space, the venting system is defective.

The defect may be caused by several conditions. Most commonly is an incorrectly installed vent cap on the outside vent pipe. As noted in detail above. The other may be a clogged, bent, damaged and or somehow restricted venting pipe.

In rare but possible instances, an interior inside the room and or closet space the appliance is in can cause a reverse venting effect. Professional help is highly suggested.

-

T-Stat Test:

A quick test of the thermostat may be to remove the temp knob. Rotate the key point the knob is attached to. Use your fingers. Turn it clockwise to it’s max amount. The burner should fire up. If not, the thermostat may have already heated the water to it’s maximum or recently turned off.

If the pilot light is not on or goes out repeatedly or occasionally, the information provided below may help to determine the problem and help to resolve it.

-

Replacing a Thermocouple:

Usually the pilot will go out if a thermocouple is defective. Usually but not always. Replacing the thermocouple may correct the problem of pilot outages.

If the pilot is present on, allow time for the T-Couple to cool. About 15 minutes. You should hear a click shortly after the pilot flame goes out. The click is a tiny sound so you must listen carefully.

After 15 minutes attempt to relight the pilot. Rotate the top selection knob to PILOT. Depress the “RED” button and hold it down while lighting the pilot. Continue to hold that red button down for 1 full minute.

After that 1 minute time has passed, release the red button. The pilot flame should remain on. If not, the T-Couple is defective and must be replaced.

If replacing the T-Couple does not resolve the pilot outage problem, the part is installed correctly and being heated correctly and fully, (all BLUE pilot flame) replacing the magneto may be required. Replacing the mag and the T-couple does not correct the problem, the thermostat is defective.

-

Magneto Replacement:

Replacing this part is not difficult. The magneto is the part the threaded end of the thermocouple screws into. It’s located on the control valve. Left side under the temp adjustment dial.

The magneto is the part the threaded end of the thermocouple screws into. It’s located on the control valve. Left side under the temp adjustment dial. Should have a red cap on it.

The part threads out of the control. Replacement is easy. Use a light amount of tension when tightening in the new part. Do not apply any thread compound to the threads. They must be grounded to the control. Thread compound will reduce metal to metal contact.

-

Pilot Lighting Instructions:

The correct procedure is to always use EXTREME caution at all times. For personal safety, turn the selector knob to the “OFF” position and wait 5 minutes.

The pilot assembly will be at the end of the aluminum pilot tube exiting the gas control valve. The correct place to light the pilot, will be at the very top of the assembly up inside the firebox.

After the pilot lights, continue to hold that reset button down for about 45 to 60 seconds or so, then release it. The pilot flame should remain “ON.” If the pilot flame remains on, stand back at arms length. Rotate the selector knob to the “ON” position.

The control knob on the top of the thermostat control will have a “Pilot” position. Turning that round control knob to this position will allow you to lite the pilot while depressing the “Red” button.

The “Red” reset button must be held down in the depressed position for at least 60 seconds before releasing it. If the pilot remains ON, turn the control knob to the “ON” position and the main burner should fire up.

If the main burner does not light up, raise the thermostats temperature to maximum to allow the burner to light up and then lower it to your desired temperature.

-

No Pilot Gas Problems:

The most common reason why pilot gas will not come out of the pilot orifice in the burner assembly has rust and corrosion.

Gas appliances left unused in vacation homes etc will buildup rust and corrosion in the pilot assembly. To correct this type of problem, first remove the pilot tube from the control.

The tube is the thin aluminum tube on the right hand side under the control. Once it is removed, turn the control to the pilot position and depress the red reset button for only 1 or 2 seconds.

Doing this is to insure that pilot gas is in fact coming out of the control and is turned on at the inlet supply pipe. If gas does come out, the pilot assembly is clogged up. If gas does not come out, the gas is off at the isolation valve on the gas supply pipe or the control is defective, etc.

The entire burner assembly will then have to be removed, the pilot assembly disassembled and cleaned out, reassembled and the entire burner assembly reinstalled back into the firebox.

Be sure to reinstall the burner assembly exactly as it current is. Burner assembly must be level and the leading edge at the front of the burner installed into the flange in the lower pan in the firebox.

Once all this is accomplished, soap test for minor gas leaks all the connection points you disassembled. The pilot must be on to leak test the pilot tubing connection and the burner must be on to test the burner tube.

If any of the repairs, methods, procedures is or appears to be more difficult than you care to attempt, some gas supply companies provide these services. Basic maintenance procedures are given in the manufacturers provided owners manual and on the labels attached to the appliance.

-

Water Heater Leaks?

- Leaking at connections on top of water heater

- Tighten up and/or replace flex connectors on water heater.

- Leaking from bottom of heater

- Time to replace the water heater.

- Leaks through drain valve at bottom of heater

- Close faucet/spigot tightly and/or have it replaced and/or do-it-yourself.

- Leaks through T&P Valve

- Replace Valve

Water Heater Issues Q & A

Q: After taking shower hot water heater makes loud pinging sounds while hot water heater is warming back up (like hitting a metal hammer against a pipe.) i believe the sound is coming from the unit, which is a gas hot water heater. i just bought the house. The heater looks about 5 years old. capacity is 50 gallons. any ideas what it could be? Should I be concerned?

A: The sound you are hearing is probably deposits on the bottom of the tank. When the heater kicks on, it has to heat these deposits before it can get to the water. This causes the pinging sound. It also wastes energy (dollars). You need to drain and flush the heater

Q: My electric water heater isn’t heating the water, I might get a short bit of hot water sometimes, but other times, it is all cold water only.

A: Replace both Upper Stat and Lower elements. Turn electrical power off before working on heater!

How to test electric water heater elements:

- Turn off the power at the circuit breaker and remove the metal covers to expose the thermostats and elements. Make sure the power is off by touching the electrical connections with a noncontact voltage detector.

- Now test the wires leading into the water heater. If they’re covered by metal conduit, the tester won’t read voltage. Instead you’ll have to remove the metal thermostat cover on the side of the water heater, pull out the insulation and hold the tester near the wires leading into the top of the high-temperature cutoff switch.

- Test both hot wires. Then hold the tester against the metal water heater shell. If the tester doesn’t light up, it’s safe to test the elements.

- Clip the alligator clamp onto one of the element screws and touch the other screw with the tester probe. If the tester doesn’t light, replace the element.

Most residential electric water heaters have two heating elements: one near the top of the tank and one near the bottom. Power enters the top and runs to the high-temperature cutoff switch, and then to the thermostats and elements. The top and bottom elements are controlled by separate thermostats. When the water on the top of the tank is hot, the top element turns off and the lower one heats. The upper and lower heating elements never come on at the same time.

Most residential electric water heaters have two heating elements: one near the top of the tank and one near the bottom. Power enters the top and runs to the high-temperature cutoff switch, and then to the thermostats and elements. The top and bottom elements are controlled by separate thermostats. When the water on the top of the tank is hot, the top element turns off and the lower one heats. The upper and lower heating elements never come on at the same time.

Q: The breaker for my water heater keeps tripping at the power panel, what could be the cause?

A: Reset breaker at the main electrical panel. If an electrical problem persists, could be the bottom element is burned and/or shorted out and/or there is an electrical problem within the electrical power supply system. *An electrician may be needed to locate and correct any problems with the electrical power supplied to the water heater.

The electrical power supplied to an electric water heater is 220 to 240+ volts! If you are not highly qualified to do electrical work, hire a professional.

Q: My hot water appears discolored and has a slightly musty odor, what could be causing this, as my cold water doesn’t have this issue?

A: Rust-colored water can be caused by corrosion inside a glass-lined tank or a failing sacrificial anode rod. If the anode rod is failing, replace it with a magnesium anode rod.

A decaying sacrificial anode rod can also release hydrogen, causing a smell like rotten eggs. To address this, first flush the water heater. Then treat the tank and pipes for two hours with a solution of 2 pints of 3 percent hydrogen peroxide to 40 gallons of water. If the smell persists, replace the failing anode with a zinc-alloy anode. If the smell still doesn’t go away, replace the heater with a plastic-lined one.

Comments are closed, but trackbacks and pingbacks are open.